Die production

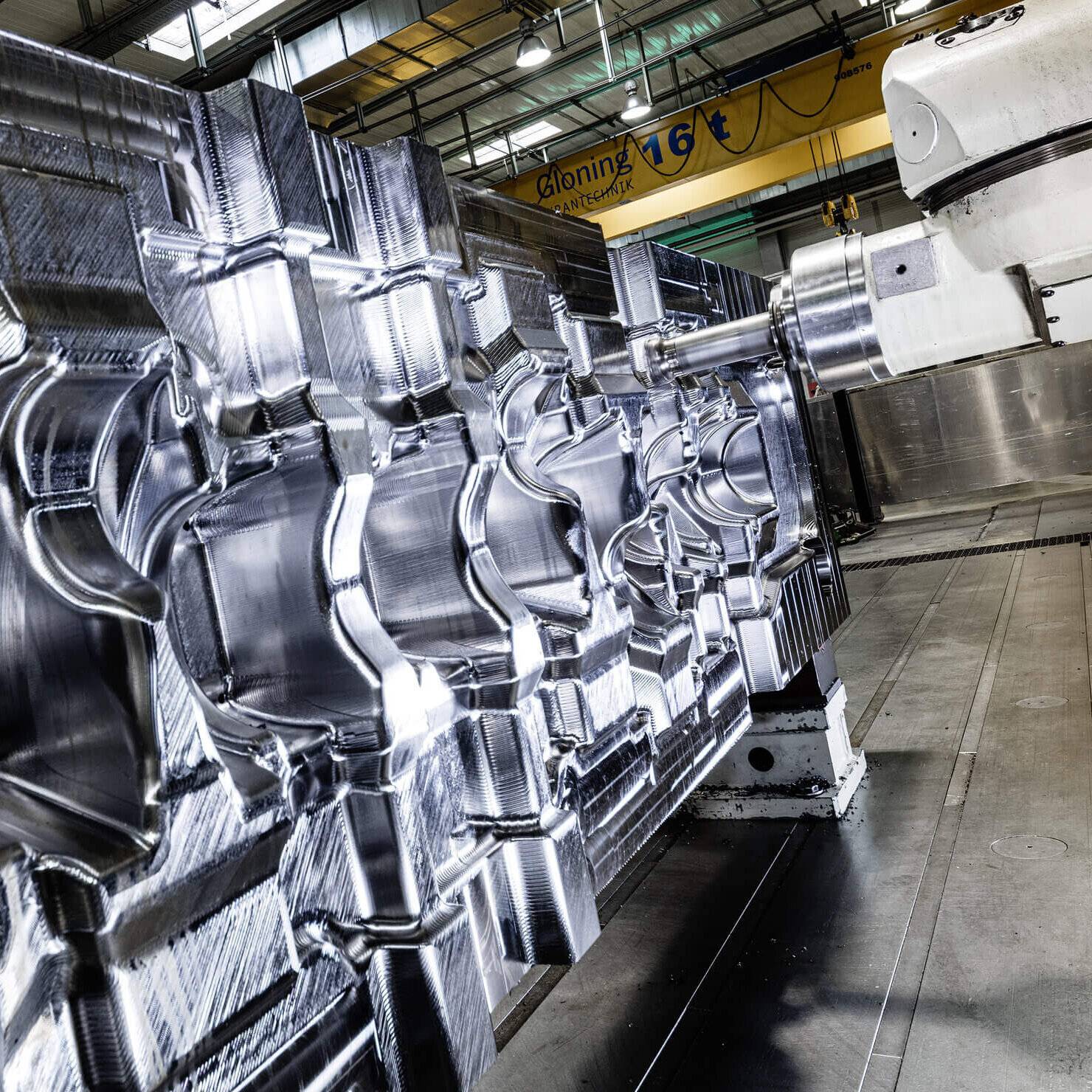

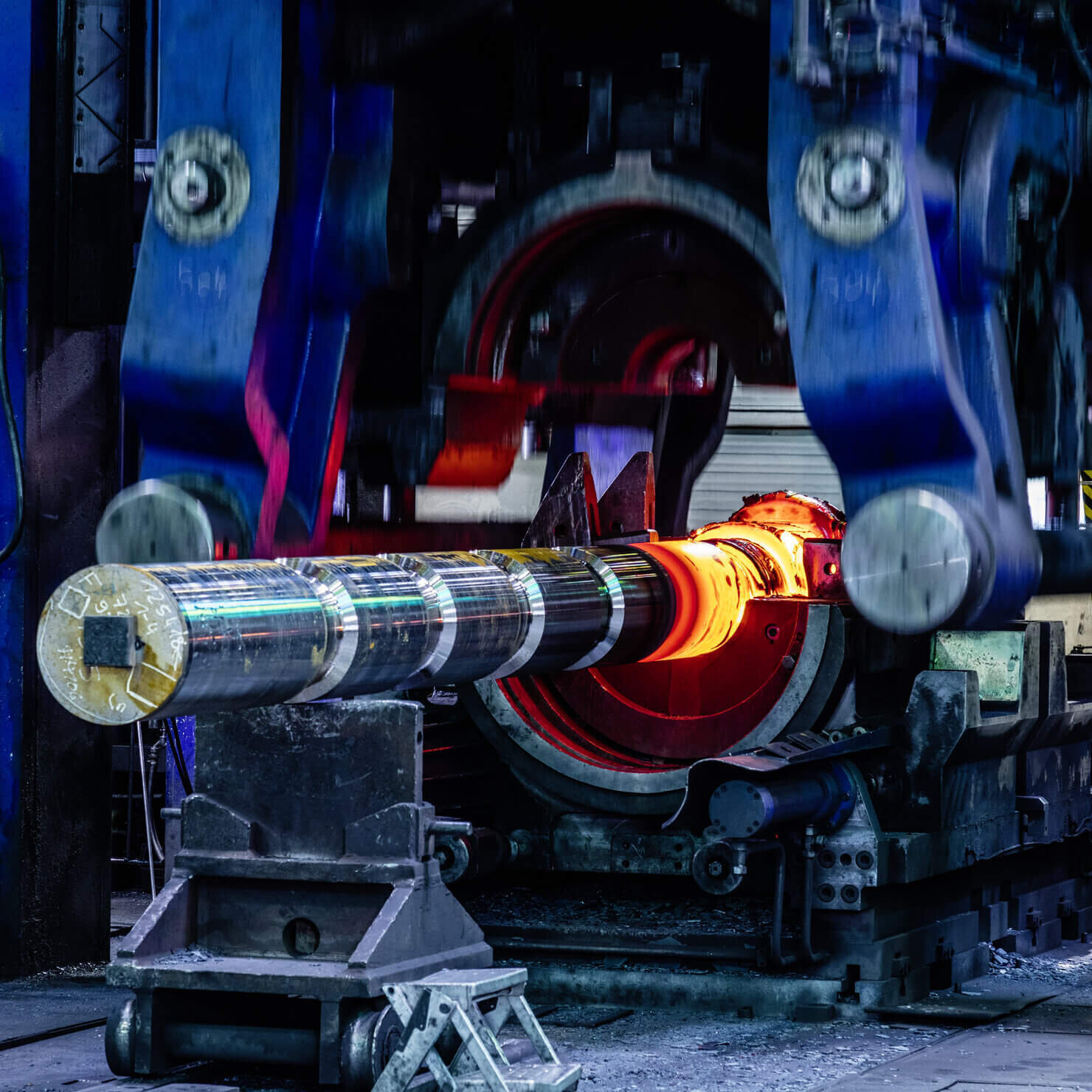

We drop-forge raw parts with a length between 1.5 and 4.5 m. The forging dies are manufactured on high-precision CNC milling machines. As a result, far fewer machining allowances are required for mechanical production. CNC programs for the production of our dies are created from the 3D model of the forging blank using CAD/CAM interface.