Inductors

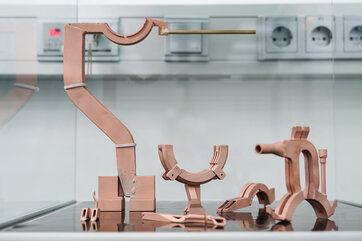

A hardening machine is only as good as the inductors used as the central tool. For this reason we develop and manufacture our inductors in-house. Our experienced employees manufacture all inductors with first-class materials and the highest level of craftsmanship. From the manufacture of the components for the heating loops and housing through to the assembly of the finished system, everything is "Made by Alfing".

Already since 2019: Production of the inductors in additive 3D printing from Alfing

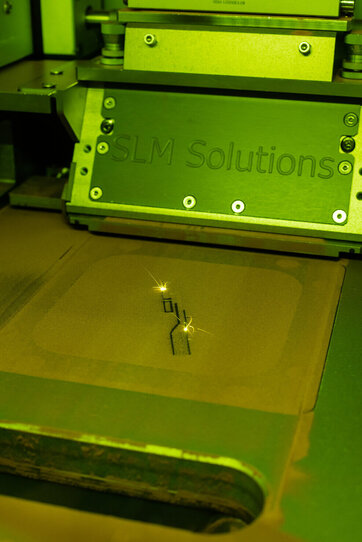

We manufacture our 3D printing inductors using selective laser melting in our own 3D technology center in the hardening machines division. The implementation of 3D printing of inductors to serial production took place in our technology center.

With selective laser melting, the material to be processed is applied in powder form in a thin layer to a base plate. The powder is completely remelted locally using laser radiation and forms a solid layer of material after solidification. The base plate is then lowered by the amount of one layer thickness and powder is applied again. This cycle is repeated until all layers have been remelted. The finished component is cleaned of excess powder, processed as required or used immediately.

Compared to the conventional manufacturing process, laser melting distinguishes itself as a formless production while reducing the time to market. In addition, there is a great deal of freedom in geometry, which cannot be produced with mold-related processes, or can only be produced with great effort.