Engineering

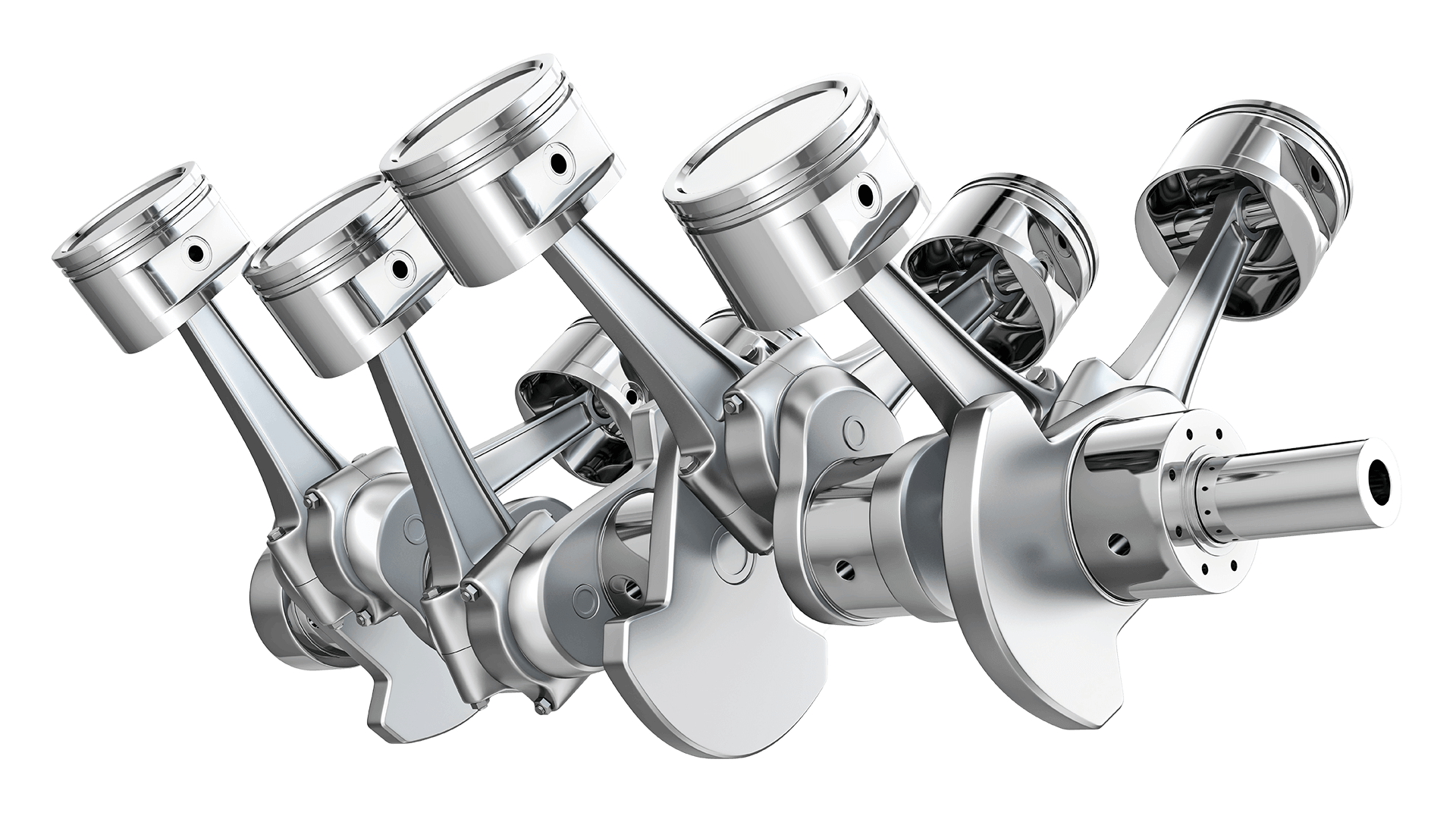

We create a 3D model of the desired component from the customer data, derive condition drawings from it, construct the necessary operating resources, create the work plans, CNC programs and design the tools for this. We rely on the latest machine technologies with maximum flexibility thanks to a wide range of special solutions.

All parameters of the design are defined and optimized together with the customer: Materials, external shapes, radii, oil drilling systems, surface treatment and counterweights etc.. Our specialists accompany all sub-processes from planning to material procurement, laboratory tests and simulations to certification and delivery of the ready-to-install components. State-of-the-art CAD/CAM systems enable direct data exchange with customer systems. The seamless interaction of all processes ensures maximum efficiency.

CAD/FEM Simulation

Right from the start of the project, we can use our CAD/FEM system to examine 3D data of our customers to determine component stress. For example, optimisation suggestions can be derived and developed by flexural and torsional fatigue strength simulations.

Process development to increase performance

Our core competencies include development, design optimisation and production technology from prototype to series. Our CAD competencies include data transfer to all customer systems, FEM simulation and dynamic balancing analysis.