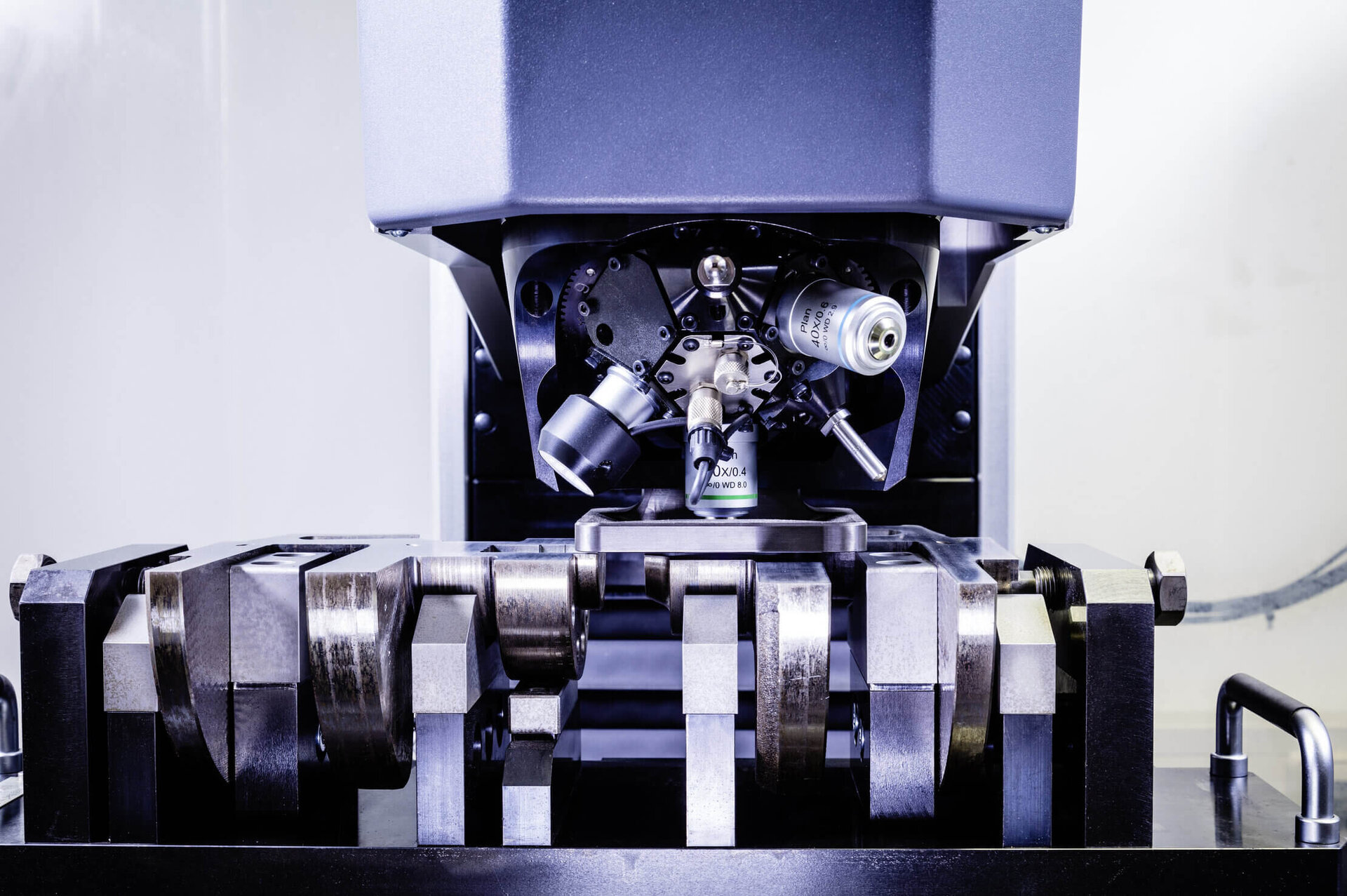

Non-destructive testing

Our staff is qualified and certified in accordance with ISO 9712 and is therefore able to carry out fluorescent magnetic particle testing (MT), dye penetrant testing (PT) and ultrasonic testing (UT).

Ultrasonic testing via phased array or non-destructive testing of hardened surface layers (CHD) can be used to meet the latest technological requirements.