Questions about our hardening machines or inductors?

Get in touch with us!

We will be happy to discuss your concerns and questions about our products. We look forward to your call or e-mail.

Sales International

Herr Grundler

Tel: +49 (0) 7361 501 1266

E-Mail: hardening@mafa.alfing.de

Sales National

Herr Buchinger

Tel: +49 (0) 7361 501 1266

E-Mail: hardening@mafa.alfing.de

Sales Asia

Liang Zhang

Tel: +86 21 / 50792585

E-Mail: hardening@mafa.alfing.de

Questions about our hardening machines or inductors?

Get in touch with us!

We will be happy to discuss your concerns and questions about our products. We look forward to your call or e-mail.

Sales International

Herr Grundler

Tel: +49 (0) 7361 501 1266

E-Mail: hardening@mafa.alfing.de

Sales National

Herr Buchinger

Tel: +49 (0) 7361 501 1266

E-Mail: hardening@mafa.alfing.de

Sales Asia

Liang Zhang

Tel: +86 21 / 50792585

E-Mail: hardening@mafa.alfing.de

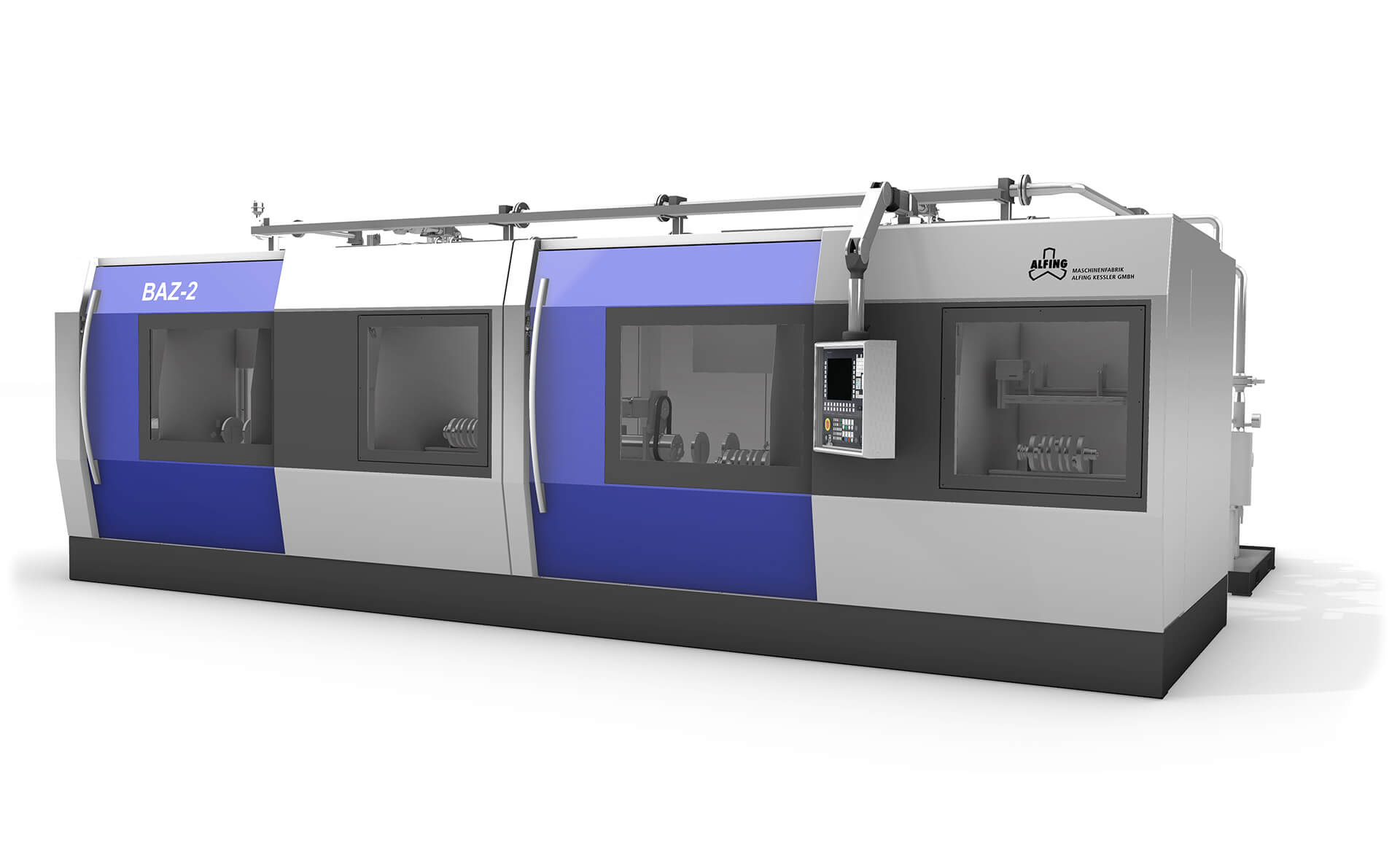

![[Translate to English:] härtemaschine automotive kurbelwellen BAZ-2 alfing kessler mafa](/fileadmin/_processed_/8/7/csm_haertemaschine-automotive-kurbelwellen-BAZ2-alfing-kessler-mafa_c434a7b78e.jpg)

![[Translate to English:] härtemaschine automotive kurbelwellen FAST-NG alfing kessler mafa](/fileadmin/_processed_/6/2/csm_haertemaschine-automotive-kurbelwellen-FAST-NG-alfing-kessler-mafa_683c197f2c.jpg)

![[Translate to English:] härtemaschine automotive kurbelwellen FAST-NG alfing kessler mafa](/fileadmin/_processed_/1/f/csm_haertemaschine-automotive-kurbelwellen-FAST-NG-img-alfing-kessler-mafa_bd2b6f1a6b.jpg)

![[Translate to English:] Härtemaschinen für LKW / Bus / Agriculture Kurbelwellen](/fileadmin/user_upload/alfing/produkte/haertemaschine-lkw-gross.jpg)

![[Translate to English:] Härtemaschine für Großkurbelwellen](/fileadmin/user_upload/alfing/produkte/haertemaschine-grosssskurbelwelle-gross.jpg)